In addition to the traditional cost constraints involved with design and construction, project owners are pushing for extremely quick and effective response from professional providers to bring new transportation systems online faster than before. To meet the demands of these new expectations, compressed schedules for the completion of new roadway projects have added the necessity for innovation from individual and team transportation design professionals.

SAM had the opportunity to provide unconventional solutions, within one company, as part of a team faced with these challenges. Originally, we were asked to provide engineering support services within the project limits including a) recovery, verification and densification of existing horizontal and vertical primary project control, b) utility coordination and Quality Level A SUE, c) drainage channel and creek cross-sections d) location of all curb inlets, location of storm drain features including inverts of all incoming and existing pipes, e) location of geotechnical bore holes, f) cross sections of all intersecting side streets for a distance of 500-feet, g) detailed design surveys for twelve (12) bridge structures and h) compilation of provided datasets by others (including aerial photogrammetry DTM’s and 3D MicroStation© DGN’s from on-the-ground conventional surveying) into one digital terrain model.

As the project developed, SAM was contracted with additional tasks including aerial photogrammetry to develop a DTM for US 281, Quality Level A SUE, and cross-sections of all entrance and exit ramps along US 281 and Loop 1604 within the project limits.

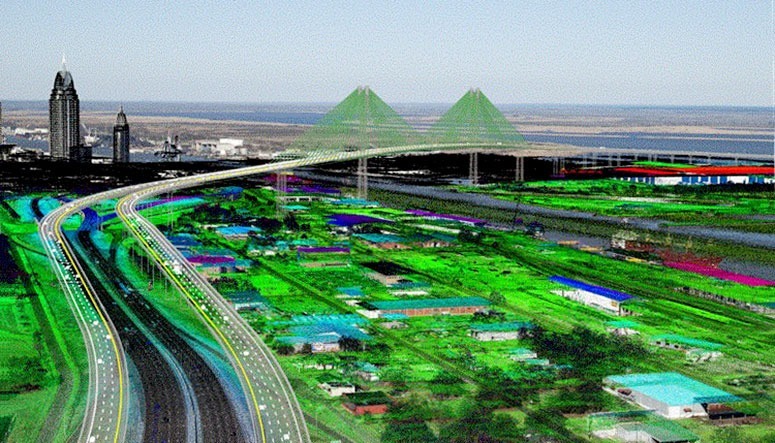

SAM was able to successfully evaluate each requested task, choose the most appropriate tool for each based on the required accuracy and precision, as well as the impact to cost and project schedule, and deliver an enormous amount of survey data within a compressed and rigid deadline. Benefits of the use of these surveying and mapping technologies for transportation design include minimal to no impact on the use of the system by the public, as well as the reduced safety risk to both survey personnel and the public, due to the ability to capture information from remote locations. The complete geospatial approach was instrumental in delivering an enormous amount of survey data within a compressed and rigid deadline.

Surveying

SAM performed a static GPS survey, per Federal Geodetic Control Committee (FGCC) Class C specifications, of all recovered monuments from the two previous surveys and additional control set by SAM for this project. In addition, using Leica© digital levels, precise level loops were performed per FGCC specifications throughout the project to include all recovered and newly established primary control within the project limits. The final adjusted elevations were included in the static GPS network adjustment.

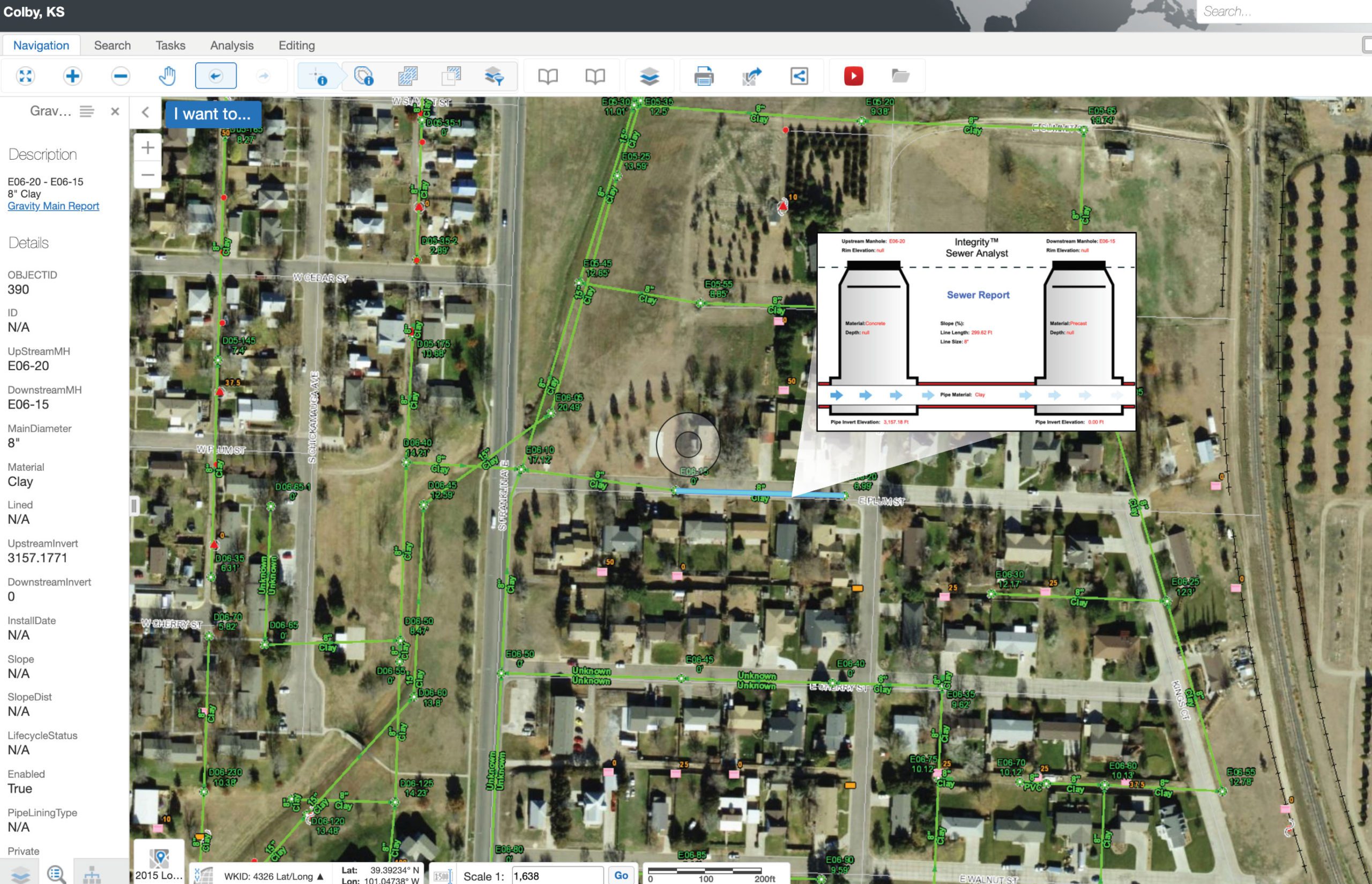

Subsurface Utility Engineering

SAM provided Quality Level B services for 2 miles along Loop 1604 and 4 miles along US 281. This included identifying, designating and mapping storm drain, water, wastewater, electric, gas, petroleum, communications and cable TV systems. This service included utility coordination for record research and field surveying utility surface features. Identification of overhead utilities (i.e., electric, telecommunications, and cable TV) systems was also provided. This project included 288,370 linear feet of Quality Level B services and a total of 67 test holes for Quality A services.

HDS Laser Scanning – Bridges

SAM provided sub centimeter level accuracy for edge of and cross slope of bridge deck, face of abutment backwall, centerline of each bent, inside edge of top of deck at 1/5 point intervals on each span, bearing seat elevations, and centerline of existing bridge columns by capturing the data using HDS. Once captured, the hundreds of laser scanned data points that comprised the planar surfaces of the desired objects were modeled and intersected to create vertices at the requested location with a much higher level of accuracy and precision than if located by any other available means. Horizontal and vertical positions at these vertices were extracted; feature attributes were attached and exported as an ASCII point list. In addition to providing the requested survey information, the entire bridge structure at each location was scanned. This allowed the capture of additional survey data for later use without the need to revisit the site in the field, which would negatively impact the project schedule.

Aerial Mapping

On short notice, SAM was contracted to provide an aerial mapping DTM, suitable for one-foot contours, of this area. During the compilation, DTM breaklines and mass points were developed constraining to all on-the-ground surveyed positions. This method ensured the higher level of accuracy and precision obtained from conventional on-the-ground surveys was utilized during compilation.

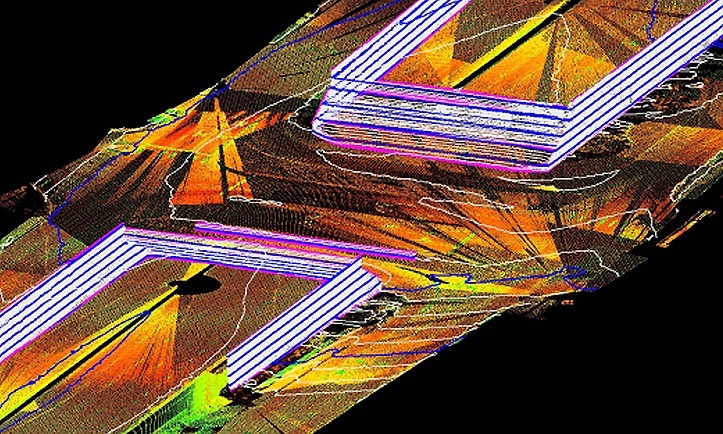

HDS Laser Scanning – DTM

Roadway DTM survey information was needed for the existing portion of the US 281 main lanes at the tie in of the proposed direct connectors. Approximately 10,500 linear feet of northbound and southbound main lanes and frontage road of US 281, and an additional bridge structure were captured using the Leica© HDS3000 laser scanner with no lane closures, disruption of normal traffic flow, or occupation of the roadway by survey personnel. Individual scans were registered together based on project control to create a georeferenced point cloud dataset. Using this dataset, breaklines and mass points were developed and exported. These features were imported into a MicroStation DTM file from which a triangulated irregular network (TIN) was produced with sub centimeter level accuracy.

Upon completion of all survey tasks, SAM created a TIN in Geopak© from all datasets developed for the project including the provided existing aerial mapping of Loop 1604, provided on-the-ground surveys of US 281, SAM aerial mapping DTM, obscured areas in the SAM aerial mapping as surveyed on-the-ground, drainage\creek\side street cross sections and HDS surveys of main lanes and frontage roads. Within the final MicroStation© DTM, the TIN hull (bounds) of the individual datasets was displayed and metadata attached defining the accuracy and precision obtained within each. This not only establishes confidence for the engineers using the respective datasets but avoids the possible uses of survey data for purposes other than originally intended at a later date by others.